When electrical systems fail in a commercial or industrial environment, the impact is immediate: production slows, safety margins narrow, and costs rise. Many faults look similar on the surface—nuisance tripping, intermittent outages, erratic motor behaviour—but the root causes often hide deep within design decisions, protection settings, ageing infrastructure, or control logic. This is where SCI’s diagnostic approach stands apart.

Founded and led by Keith Walton—an experienced electrical and mechanical engineer—SCI brings engineering rigour to commercial fault finding. We combine deep technical analysis with disciplined on-site process to pinpoint causes quickly, resolve issues with minimal disruption, and leave systems safer and more reliable for the long term.

This article explains how we work, why engineering leadership matters, and what outcomes you can expect when the fault is anything but straightforward.

What Makes Commercial Faults So Complex?

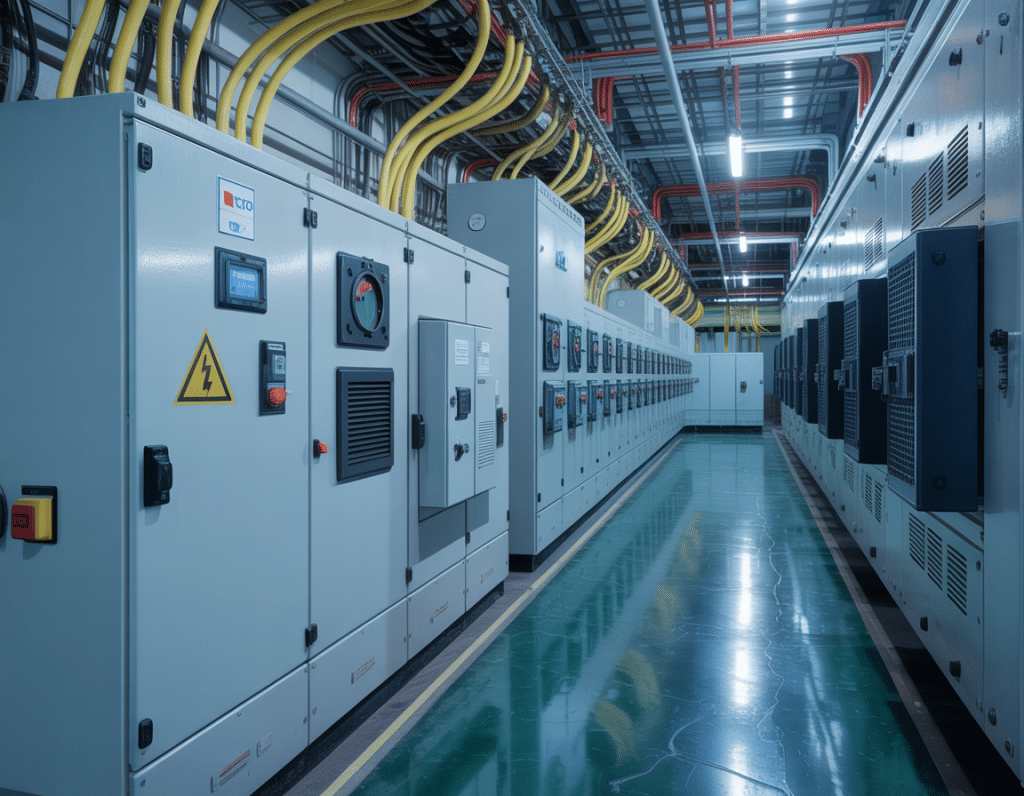

Commercial and industrial sites are not simple ring mains and consumer units. They are layered systems with interdependent components:

- Three-phase distribution with selective protection and discrimination requirements

- Variable speed drives (VSDs), soft starters, and power factor correction

- Building management systems (BMS) and PLC-based control

- Emergency systems (fire alarms, emergency lighting, life safety supplies)

- Legacy circuits integrated with new equipment

- Harmonic-rich loads and sensitive electronics

When something goes wrong, multiple symptoms can mask the real failure. A tripping breaker may be protecting against inrush, harmonics, or a mis-specified cable; a “failing” motor might be a ventilation, bearing, or supply quality problem. Untangling these paths requires method, measurement, and experience.

The SCI Difference: Engineering at the Core

Keith Walton’s engineering background sets the tone for SCI’s method. We treat every fault like a technical investigation, not a trial-and-error exercise. That difference shows in four areas.

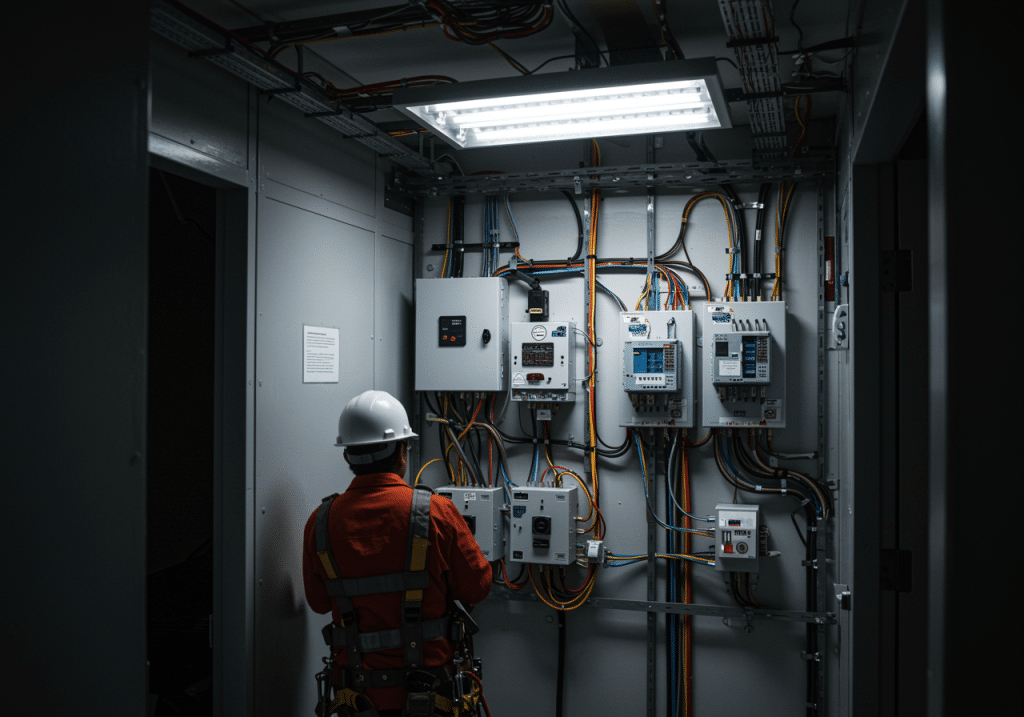

1) Structured Diagnostics

We follow a clear sequence:

- Define the fault precisely: When does it occur, under what loads, after what changes?

- Stabilise the environment: Ensure safe conditions, isolate variables, and avoid cascading failures.

- Test hypotheses with data: Use calibrated instruments and, where needed, temporary monitoring to confirm or rule out causes.

- Fix and validate: Apply the remedial action, then verify with repeatable tests and documentation.

This approach reduces guesswork, shortens downtime, and prevents repeat visits.

2) Advanced Instrumentation

We use calibrated test equipment suited to complex environments:

- Power quality analysers to capture harmonics, transients, flicker, and sags/swells

- Clamp meters and inrush current logging for accurate start-up profiling

- Insulation resistance, continuity, and loop impedance testers for BS 7671 compliance

- Thermal imaging to identify hidden heating at terminations and within panels

- Data logging on key circuits to identify intermittent faults over time

Accurate measurements allow precise fixes rather than blanket replacements.

3) System-Level Thinking

We look beyond the failed component. Protection settings, discrimination curves, earthing arrangements, cable selection, and enclosure ratings all influence outcomes. SCI assesses how loads interact, how controls respond, and how future expansions will change fault levels. This reduces the risk of shifting problems elsewhere in the system.

4) Documented, Compliant Outcomes

We provide clear reporting—fault description, test results, root cause analysis, actions taken, and any recommendations. This supports compliance under BS 7671 and the Electricity at Work Regulations and helps facilities teams maintain standards after we leave.

How Our Process Minimises Disruption

Unplanned downtime is costly. SCI designs interventions to keep your site operational wherever possible.

- Staged investigation: We plan diagnostics around production schedules, targeting low-impact windows for intrusive tests.

- Temporary workarounds: Where safe, we isolate affected sections or deploy temporary supplies to keep critical areas running.

- Rapid triage: We separate safety-critical faults from performance issues and address the highest risks first.

- Clear communication: You get a timeline, what we are testing, and what services may be affected so you can plan ahead.

The result is a shorter path from “problem” to “back online,” with fewer surprises.

Practical Scenarios: Where SCI Adds Value

Scenario 1: Nuisance Tripping on a New Production Line

Symptoms:

- A 75 kW motor on a conveyor line intermittently trips a downstream breaker during start-up.

- Multiple electricians replaced the breaker and checked the motor; the issue returned within days.

SCI’s approach:

- Logged inrush current and power quality during several start cycles.

- Reviewed protective device selection against manufacturer curves and cable sizing for voltage drop.

- Identified a mismatch: the breaker’s magnetic trip setting lacked headroom for the actual inrush profile.

- Recommended a correctly rated device with appropriate characteristics and adjusted start parameters on the VSD.

Outcome:

- Stable operation with no further trips.

- Documentation supplied for future maintenance and insurer records.

- Zero component replacement beyond the mis-specified device.

Scenario 2: Erratic LED Lighting and Control Failures in an Office Block

Symptoms:

- Flickering LED panels, BMS alarms, and occasional emergency lighting test failures.

- Prior contractors suspected “bad fittings” and swapped luminaires without lasting improvement.

SCI’s approach:

- Conducted a harmonic survey and neutral current analysis across floors.

- Found elevated THD due to a high density of switched-mode power supplies, stressing neutrals and upsetting control signals.

- Implemented harmonic mitigation through distribution changes, installed additional neutral capacity on key runs, and adjusted control wiring segregation from power runs.

Outcome:

- Stable lighting and reliable BMS communication.

- Clear guidance for future tenant fit-outs to avoid reintroducing the issue.

- Audit-ready documentation for facilities management.

Scenario 3: Intermittent Earth Faults in a Food Processing Plant

Symptoms:

- Periodic RCD trips in wet areas, no clear pattern.

- Production downtime during cleaning cycles.

SCI’s approach:

- Time-correlated RCD trips with cleaning schedules using data logging.

- Inspected IP ratings and cable entries; thermal imaging showed moisture pathways at poorly sealed gland plates.

- Reworked gland terminations, upgraded to appropriate IP-rated enclosures, and separated circuits for better selectivity.

Outcome:

- No trips during subsequent cleaning cycles.

- Improved safety margins and lower maintenance call-outs.

- Updated drawings and a maintenance checklist for sealing inspections.

Scenario 4: Transformer Overheating in a Mixed-Use Facility

Symptoms:

- LV transformer running hot under moderate loads; upstream alarms triggering.

- Concern over premature failure and energy losses.

SCI’s approach:

- Power quality analysis revealed significant triplen harmonics from non-linear office loads back-feeding via shared distribution.

- Recommended K-rated transformer or reconfiguration of load grouping, and installed passive filtering at key panels.

Outcome:

- Reduced operating temperature and improved efficiency.

- Lower risk of unplanned outages.

- Energy savings with measurable payback.

Why Keith Walton’s Engineering Background Matters

Leadership grounded in engineering shifts the conversation from symptoms to systems. Practical benefits include:

- Correct interpretation of protection and discrimination curves

- Accurate load and fault level calculations for expansions and upgrades

- Integration of mechanical considerations (cooling, vibration, enclosure ventilation) that affect electrical reliability

- Informed selection of materials and devices based on real duty cycles, not catalogue assumptions

- Effective liaison with OEMs, insurers, and auditors using technical evidence rather than anecdote

This depth is especially valuable when faults sit at the interface between disciplines—electrical distribution, drives, controls, and mechanical plant.

Safety and Compliance Built Into Every Step

Fault finding is not only about getting you running again. It is about ensuring the system is safe and compliant:

- Testing to BS 7671 with calibrated equipment

- Clear records: Electrical Installation Certificates (EIC), Minor Works Certificates, and updates to EICRs where remedials are completed

- Verification of earthing and bonding integrity after any intervention

- Recommendations to improve selectivity and reduce future risk

- Guidance for inspection intervals and planned maintenance, aligned with your insurer’s requirements

By closing the loop from diagnosis to documentation, SCI gives you traceability and peace of mind.

Long-Term Reliability: Designing Out Recurring Problems

Many faults recur because the underlying design or operating conditions remain unchanged. SCI aims to design out future failures by:

- Addressing root causes rather than treating symptoms

- Improving cable management, enclosure selection, and ventilation

- Optimising protection coordination and RCD/RCBO selectivity

- Reducing harmonic stress and neutral loading

- Ensuring accurate as-fitted documentation to support maintenance

These measures reduce call-outs, protect equipment, and extend asset life.

What You Can Expect When You Engage SCI

- A clear plan before we touch a panel: scope, risks, and expected outcomes

- Minimal disruption through staged work and careful isolation

- Transparent findings with data to support decisions

- Remedial work carried out to a high standard, with full certification

Practical advice to reduce future risk and cost

When to Call Us

If you are facing any of the following, SCI can help:

- Repeated breaker trips or unexplained shutdowns

- Sensitive equipment misbehaving after upgrades

- Heat build-up in panels or transformers

- Intermittent RCD trips in wet or washdown areas

- Flicker, dimming, or control issues with LED lighting

- New machinery causing instability on existing supplies

Early intervention prevents collateral damage and shortens downtime.

Conclusion: Fast Answers, Safer Systems, Fewer Repeat Visits

Commercial fault finding demands more than replacement parts. It requires engineering logic, quality measurements, and disciplined execution. Under Keith Walton’s leadership, SCI delivers all three. We resolve difficult faults quickly, keep your operations running, and leave your electrical systems safer, better documented, and more resilient.

To discuss a current issue or arrange a diagnostic survey, contact SCI. We will provide a structured plan to find the root cause and fix it—safely and efficiently.